Integrated Project Delivery

Integrated Project Delivery (IPD) in manufacturing provides a lean approach to deliver projects in order to reap benefits as early as possible. Let’s explore the nature of manufacturing projects first and then explain how the process of IPD helps to run projects efficiently.

Not all projects are the same. Projects vary in complexity and size. Many factors contribute to complexity e.g. people, timescales, commercial pressures, health & safety, product, political pressures. Fewer factors contribute to the measurement of project size. Usually it is money and the number of physical elements in a project, but it can also be the number of people impacted and the benefits delivered.

The size of a project should not be confused with complexity, although inevitably there will be some direct proportionality. A ‘small’ project could still be very complex and hence require a disproportional amount of resource to deliver.

Typical manufacturing projects involve all or some of the following elements:

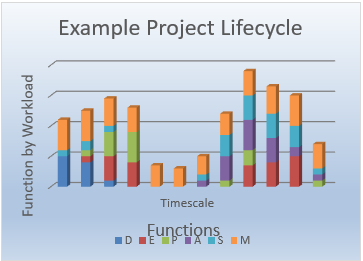

To deliver these elements, in most cases, the following functions are required:

- Design

- Engineering

- Safety

- Procurement

- Assembly

- Management

- Quality

Each of the functions requires different amounts of effort at different times. The graph below illustrates the variability of these functions during the project lifecycle.

It is unlikely that every client will have all the resources or experience to complete large, complex, multi-disciplinary projects, therefore it will contract with the required suppliers. This does not outsource the project completely. The client’s involvement continues to be essential.

It is unlikely that every client will have all the resources or experience to complete large, complex, multi-disciplinary projects, therefore it will contract with the required suppliers. This does not outsource the project completely. The client’s involvement continues to be essential.

Integrated Project Delivery (IPD)

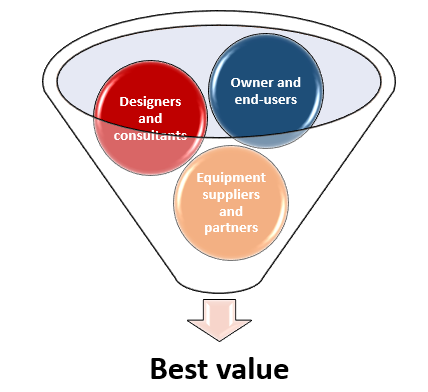

IPD is a collaborative alliance of people, systems, business structures and practices feeding a process that harnesses the talents and insights of all participants to optimise project results, reduce waste and maximize efficiency through all phases of design, fabrication, and construction thus increasing value to the owner.

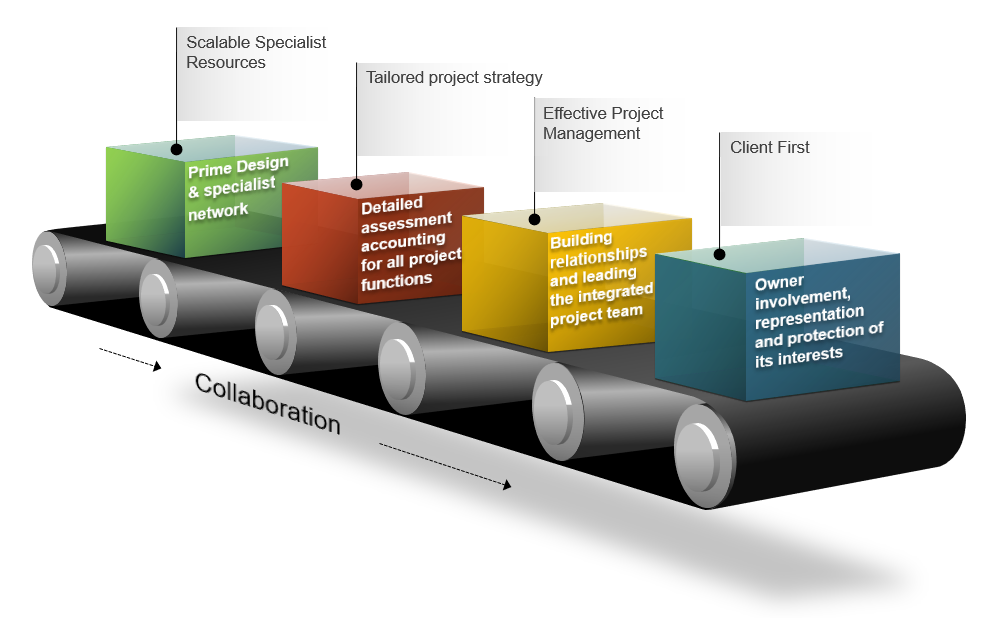

The integrated project provider has a detailed knowledge of the project, understands what needs to be done and therefore the resources required. By employing a company such as Prime Design, the owner gets access to teams of people who have already worked together and built up trust and strong relationships, in addition to its own inhouse and third-party experts. Prime Design leads and co-ordinates this “group” of teams, building trust and commitment in order to put the owner’s interests first.

The key elements of this integrated approach are:

Benefits of Integrated Project Delivery

- Lean project delivery

- Cost and time efficient

- The project owner does not need to employ full time project professionals and other resources that may be underutilised at times. The correct resources are deployed to focus on both the project and daily operations, ensuring all business plan objectives are met

all aspects of the project are considered at the concept phase, ensuring the scale and requirements of the project are known, resources are correctly allocated, budgets are more accurate.

all aspects of the project are considered at the concept phase, ensuring the scale and requirements of the project are known, resources are correctly allocated, budgets are more accurate.- Reduced risk; fewer unexpected surprises that increase delivery time and project costs

- Project professionals lead an integrated team of experts from a variety of organisations, harnessing their skills and talents.

- A network of organisations which have collaborated on previous projects provide strong relationships and effective teamwork

All leading to increased value for the project owner.

.png)