Making it Fit and Making it Work: The Importance of Factory Plant Layout and Design

When it comes to manufacturing, the design of your factory plant is essential to the efficiency and long-term success of your operation. Factory plant layout and design isn’t just about fitting everything into a building; it’s about creating a thoughtful, efficient space that enables growth, optimises productivity, and maximises profitability.

At Prime Design, we specialise in helping you navigate the intricacies of factory plant layout and design. With experience across multiple industries; including dairy, soft drinks, liquid food, infant formula, aeronautics and high-end automotive, we bring cross-industry expertise to every project.

But what exactly is factory plant layout and design, and why does it matter?

What Is Factory Plant Layout and Design?

At its core, factory plant layout and design is about understanding your production needs and aligning them with the physical space available. It involves a detailed exploration of the following:

- What you need: Identifying your factory’s current and future needs, such as production capacity, equipment requirement and workforce considerations.

- What you have: Understanding the existing layout, equipment, and infrastructure to determine how they can be optimised or reorganised.

- Designing for efficiency: Creating a layout that improves workflows, minimises waste and supports both short-term and long-term goals.

Prime Design’s expertise and processes will guide you through this journey, ensuring your plans can be executed efficiently and effectively.

Key Considerations for a Successful Factory Layout

Whether you're starting from scratch with a new factory or looking to improve your existing space, there are a few key areas you must focus on for optimal factory design:

1. Production Space:

To ensure maximum efficiency, your production space must dictate the overall design of the factory, not the other way around. The shape, size, and arrangement of production areas must be considered first, ensuring adequate space for workers, materials, and machinery to move freely.

2. Packaging Line Integration:

Many manufacturers need to plan for new packaging lines or other additional equipment. Prime Design’s team specialises in integrating these new systems into your facility’s existing layout, ensuring a seamless flow and minimal disruption.

3. Addressing Congestion:

Over time, many factory layouts become congested and inefficient as equipment, processes, and systems evolve. A redesign strategy can address these issues, freeing up space and improving overall production flow.

4. Space Constraints:

In many industries, factory space is at a premium. When additional production capacity is needed, a creative approach is essential to maximising available space without sacrificing efficiency. Prime Design has extensive experience working within space limitations, providing practical and innovative solutions.

Frequently Asked Questions

Will My Production Line Layout Impact Efficiency?

The answer is almost certainly yes. A well-designed layout is key to improving production line efficiency. The right amount of space for the flow of materials, products, and people can reduce downtime, speed up production, and increase overall output. Interestingly, a poor layout can even affect employee morale and engagement, highlighting the importance of careful planning.

Where Do I Start When Redesigning My Production Line?

Start by considering both the immediate and future needs of your factory. What processes and equipment are required? What is the available space, and can it be extended or repurposed? A feasibility study often helps determine the best layout options, and computer simulations can predict how different designs will affect efficiency.

How Can I Alter My Production Line Without Halting Operations?

This is a common concern, but there are several ways to make changes while minimising disruption. These include working additional hours, scheduling improvements during planned downtime, or phasing the changes over time. In some cases, parallel production facilities or stock-building can allow for the production line to be taken offline for improvements without affecting output.

How Can I Free Up Space in My Factory?

If you’re running out of space, start by critically assessing what you have. Does every item in your factory serve a current, critical purpose? A 5S audit (Sort, Set in order, Shine, Standardise, Sustain) can help eliminate clutter and free up valuable space. After this, reviewing and optimising your factory layout can maximise efficiency and reduce unnecessary congestion.

How Do I Make My Production Facility Lean?

A lean factory minimises waste by focusing on the 7 types of waste (transportation, inventory, motion, waiting, over-processing, overproduction, and defects). Start by benchmarking your current processes to identify inefficiencies. A proper line design, combined with lean principles, will help streamline operations and eliminate waste at every stage of production.

The Design Process at Prime Design

Factory plant layout and design is an iterative process that requires careful planning, collaboration, and analysis. The Prime Design team follows a structured approach to ensure every project is tailored to meet specific needs:

- Stakeholder Interviews: Understanding the requirements of all involved parties to ensure the design aligns with company goals.

- Facility Surveys and Architect Consultations: Evaluating the existing space and identifying any potential limitations.

- Process and Packaging Design: Ensuring that equipment and workflows are aligned with the company’s production goals.

- Line Layout Development and Simulation: Creating and testing multiple design scenarios to find the best fit.

- Cost and Budget Analysis: Preparing for all the financial considerations that come with a factory redesign.

Technology-Driven Designs

At Prime Design, we utilise cutting-edge technology to improve the design process:

- 3D Scanning: Accurately surveys existing facilities, ensuring up-to-date and precise data that can be used to validate and optimise the layout.

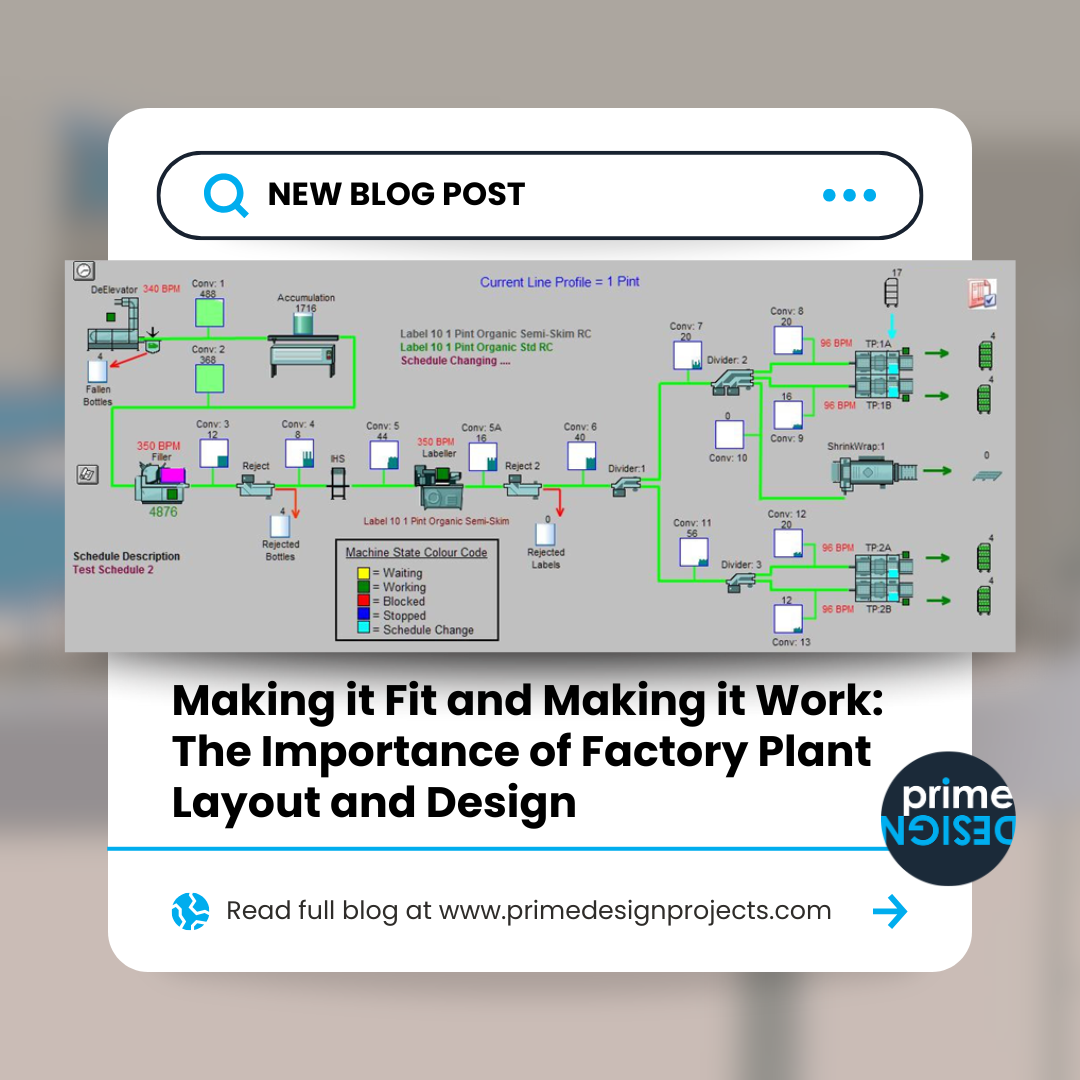

- Computer Simulations: Using tools like Simul8®, we model the production line to assess its efficiency, accounting for factors like equipment speeds, staff requirements, and expected downtime.

- 3D Modelling and Walkthroughs: Visualising the entire layout through 3D models allows stakeholders to understand the design in detail before implementation, ensuring alignment and smooth communication.

Final Thoughts

Whether you are designing a new factory or looking to optimise your existing space, factory plant layout and design are crucial to improving efficiency, boosting productivity, and supporting future growth. At Prime Design, we help you explore your needs, understand your challenges, and develop the most effective solutions; backed by industry expertise and cutting-edge technologies.

Ready to get started? Contact us today to discuss your project!

Call our team today or request a call back:

+44 (0)1784 668188

info@primedesignprojects.com