Further Information

Factory Plant Layout and Design (Design, Validate, Visualise...)

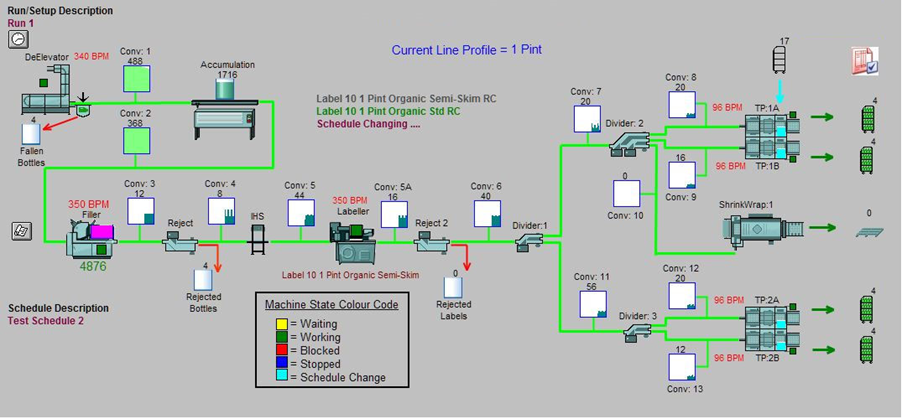

A view from a recent full line design we completed for a customer in China.

What is it all about?

This is one of the creative aspects of what we do and where it all began for Prime Design in 1992.

Factory Plant Layout and Design is fundamentally about exploring what you need in your factory, what you have already… and ultimately providing sensible, efficient schemes which can enable your plans. This is normally an iterative process involving:

- stakeholder interviews

- surveying and/or architect consultation

- process and packaging design

- staff and component movement analysis

- review of other associated space requirements

- line layout development

- line computer simulation and budget preparation

Too often, we hear of clients who are not satisfied with the project they have implemented and frequently this is due to a lack of attention to detail at the planning stage. Prime Design has the expertise and processes to help you on this journey.

Prime Design has provided facility designs in many manufacturing industries, including: dairy, soft drinks, liquid food, infant formula, aeronautics and high-end automotive so are able to bring cross-industry solutions to all projects.

Our design team utilise the latest technologies to help with efficient scheme design:

- DESIGN - 3D scanning to accurately survey your buildings and equipment and to validate existing layout information. Existing CAD drawings are often inaccurate which can cause big issues if not identified early. This technology also greatly simplifies communication to aid the physical design development process. It is much faster and cheaper to survey your facility with a 3D laser scanner and you avoid return visits for detail you may have missed traditionally.

- VALIDATE – We undertake computer simulation (Simul8®) to assess the efficiency of a line design. We take into account: individual equipment efficiencies, MTBF/MTTR, equipment speeds, line accumulation, component replenishment, number of staff to calculate expected line efficiencies. This allows us to refine line designs to give the best output.

It is much easier and safer to check how a line will run at this stage rather than when the project ramp-up begins! We strive to get the correct design up front. After all, as a fare-paying passenger you wouldn’t expect to be taking an aircraft’s maiden flight with the test pilot sitting at the front!

- VISUALISE - 3D modelling to help fully evaluate the fit, look and operability of the new designs. We provide 3D ‘walk-throughs’ of the new line to get a thorough understanding of the design to allow you to communicate and gather stakeholder support early in the process (We produce 2D designs as standard).

Related Survey and Drawing Services

As well as manufacturing plant layout and design, Prime Design routinely create and update client’s site drawings, including: full site buildings, site utilities drainage and fire systems.

We recognise how easy it is for site drawings to become outdated. Some of our customers engage us on a contract basis to keep their site drawings up to date. As part of this service we liaise with any new projects to make sure the latest information is provided and that site drawings are updated as projects are completed. This ‘peace of mind’ service is valued by many of our busy customers.

There is also a [legal] requirement for factory documentation to include up-to-date drawings of utility services and key facilities. Fire safety regulations, health and safety regulations (incl. permit-to-work), and environmental management/regulations for example will require a range of drawings including details/locations for service isolation points (steam, compressed air, water etc.), assembly points, evacuation routes, drainage and water treatment.