What is simulation?

Simulation is one of the most powerful techniques available for evaluating and analysing business processes. What sort of business processes? Well, pretty much any process that can be described and defined; from airline check-ins to supermarket check-outs, from production lines to assembly lines.

Simulation is one of the most powerful techniques available for evaluating and analysing business processes. What sort of business processes? Well, pretty much any process that can be described and defined; from airline check-ins to supermarket check-outs, from production lines to assembly lines.

Simulation: a simplified representation of real-world events which allows the understanding and solution of a problem to be achieved in a risk-free, digital environment.

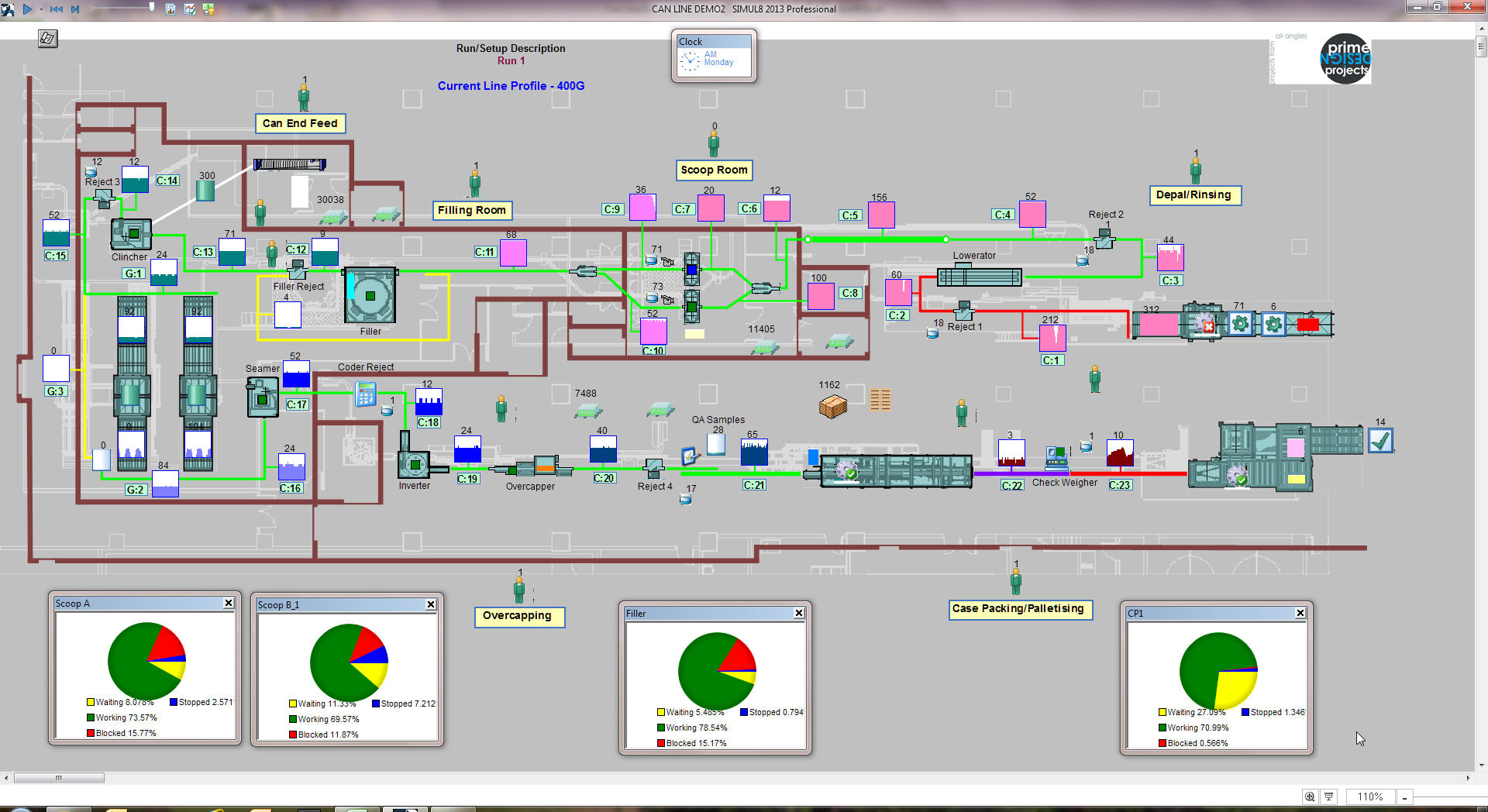

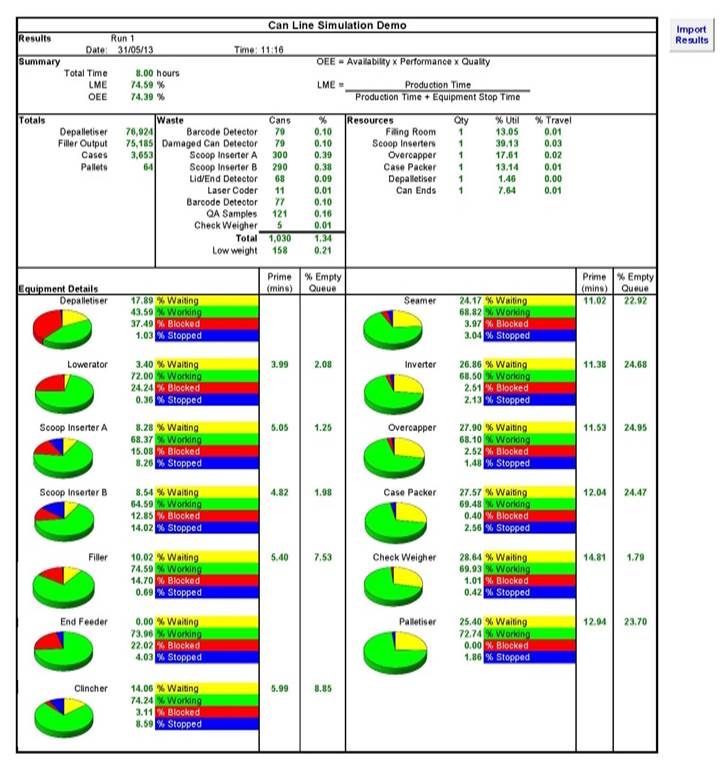

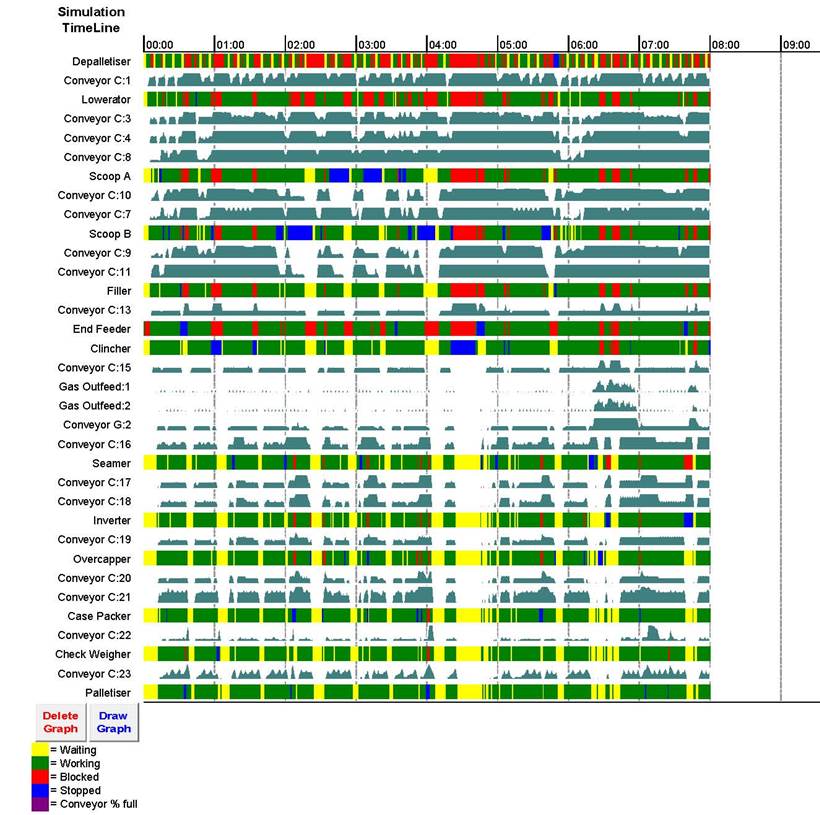

Used across many industries including: manufacturing, automotive, pharmaceutical, healthcare, supply chain and logistics. Prime Design has been using simulation modelling to benefit our customers for nearly 30 years and is a Simul8® Certified Solution Provider. www.simul8.com

It’s used to solve existing problems. It’s also used to understand and analyse new processes, designs and developments (where there is no ‘benefit of experience’). Experimenting in the real world is expensive; right first time is what we want because there’s usually a high price for getting it wrong (each time). Real world = real time: even a small change can take a long time to evaluate (more time at low efficiency if not resolved). Simulation models however can compress run time from days to minutes, evaluating many scenarios in a short time frame.

It’s used to solve existing problems. It’s also used to understand and analyse new processes, designs and developments (where there is no ‘benefit of experience’). Experimenting in the real world is expensive; right first time is what we want because there’s usually a high price for getting it wrong (each time). Real world = real time: even a small change can take a long time to evaluate (more time at low efficiency if not resolved). Simulation models however can compress run time from days to minutes, evaluating many scenarios in a short time frame.

Simulation enables informed, evidence-based decisions. It reduces risk by comparing different scenarios to evaluate the best solutions.

Simulation enables informed, evidence-based decisions. It reduces risk by comparing different scenarios to evaluate the best solutions.

Building a simulation model will:

- Improve decision making at the design phase

- Give a better understanding of the process

- Find the optimum solution through analysis of trials and scenarios

- Reduce costs by evaluating designs prior to capital submission

- Enable repeatability and consistency for tests and evaluations

- Benchmark supplier deliverables with clear expectations

- Enable better planning by considering future variables and uncertainties

- Improve confidence and communication for all members of the project team as everyone has the same understanding of the process

- Reduce risks

We regularly use simulation modelling as part of our complete filling and packaging line design process; from supply of materials to delivering the finished goods to the warehouse, allowing designers and operations teams easily to identify and eliminate inefficiencies. Other simulation applications have included:

We regularly use simulation modelling as part of our complete filling and packaging line design process; from supply of materials to delivering the finished goods to the warehouse, allowing designers and operations teams easily to identify and eliminate inefficiencies. Other simulation applications have included:

- Optimising a new high speed canning line

- Proof of packaging machine design concept

- Design evaluation and critique of a 300cpm canning line in the USA

- An assembly line simulation for a premium UK car manufacturer.

- Creation of line design improvement proposals for a UK dairy